L’avant dernière partie dédiée à la plateforme STnano : eFab, est disponible sur notre chaîne Youtube

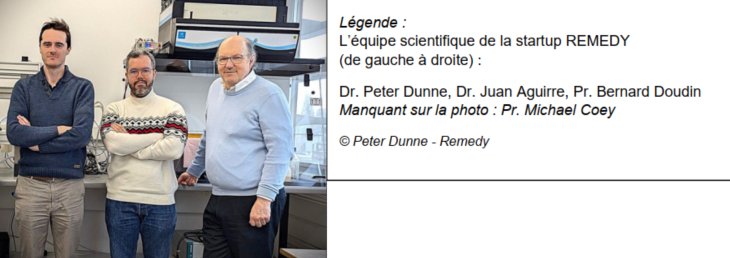

The dedicated page on the Conectus website:

https://www.conectus.fr/creation-de-la-startup-remedy-propulsee-par-la-satt-conectus-et-quest-change

Students with a Master’s degree who wish to apply for a doctoral contract are invited to send their application to the thesis director, whose contact details are given in the subject description.

You can find all the subjects proposed on the dedicated page of the ED 182 website: https://edpcp.u-strasbg.fr/?page_id=7819

Information on the timetable and how to apply is available at : https://edpcp.u-strasbg.fr/?p=319

Conception de matériaux nanostructurés à faible impact environnemental pour la production d’hydrogène par électro-catalyse /PICHON Benoît (DCMI)

Machine learning assisted first principle molecular dynamics for modelling structures and properties of disordered materials / ORI Guido (DCMI)

Etude spectrale des propriétés optoélectroniques des oxydes ferroélectriques par sonde locale / DINIA Aziz Dinia – RASTEI Mircea (Co-encadrant) (DCMI)

Photochemistry of oxazolones / HOFFMANN Norbert (DMO)

Quantum charge effects in nanoparticulate plexcitonic systems / DONNIO Bertrand (DMO)

Difluorure de bore de curcuminoïde : émetteurs pour l’électronique organique / D’ALEO Anthony (DMO)

Dynamics of charges and spins in a 2D magnet induced by a femtosecond laser pulse: FePS3 antiferromagnet / BARTHELEMY Marie & HALTE Valérie (DON)

Exploring quantum defects in 2D materials with ultrafast optical coherent microscopy / BARSELLA Alberto – FRAS François (Co-encadrant) (DON)

Influence of the environment on electron capture decay: Investigation of the microscopic nature of dark matter / HERVIEUX Paul-Antoine (DON)

Optimization and control of quantum heat engines / MANFREDI Giovanni (DON)

Quantum thermodynamics for electronic transport / WEIMANN Dietmar & JALABERT Rodolfo (DMONS)

Ab initio calculated magnetic coupling between magnetic nanoparticles on graphene / ALOUANI Mebarek – BACQ-LABREUIL Benjamin (Co-encadrant) (DMONS)

Non-linear hall effects: towards efficient electrical rectification for THZ detection / BAILLEUL Matthieu & NOËL Paul (DMONS)

Quantum spintronic qubit: first experiments / BOWEN Martin (DMONS)

Skyrmion characterisation and manipulation via a molecular spin probe / LIMOT Laurent (DSI)

This new cross-border UpQuantVal project, launched on March 3, 2025, brings together academic, research and private-sector players in the Upper Rhine region to create an integrated and sustainable tri-national quantum ecosystem.

The Communication department of IPCMS is diversifying its activities to enhance the institute’s visibility by launching a new

participatory initiative!

The goal of these episodes, presented in a brief format lasting only a few minutes, is to highlight the work, research, and individuals who contribute to the life of our laboratory.

Dans le cadre des podcasts de l’Université de Strasbourg, produit par le réseau Alumni, Martin Bowen et son équipe sont intervenus pour communiquer sur leur projet de recherche paru en 2022

System Highlights:

Research Opportunities:

Potential Applications:

High-density capacitor fabrication for advanced electronics

Exploration of ferroelectric properties in doped HfO2 films

Development of novel gate dielectrics for semiconductor and/or 2D devices

Next Steps:

This new ALD system represents a significant advancement in STnano research infrastructure, positioning us at the forefront of materials science and nanotechnology research. For more information, training sessions, or to discuss potential research projects, please contact STnano facility manager

This work has benefited from the government grant Program PEPR-Spin, project SPINMAT, operated by the French National Research Agency as part of the France 2030 program, reference « ANR-22-EXSP-0007»

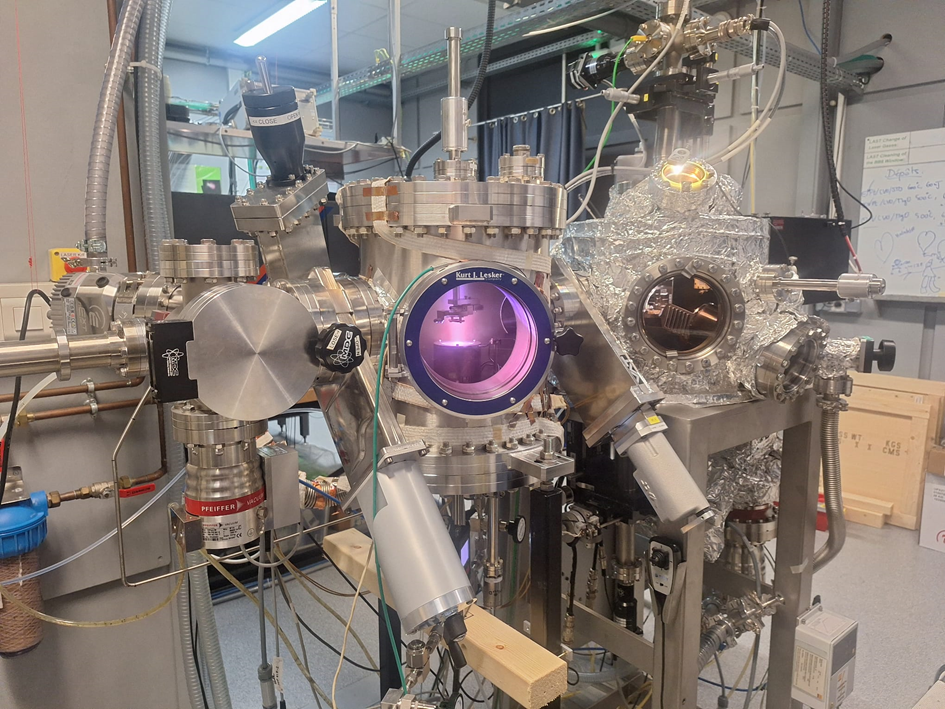

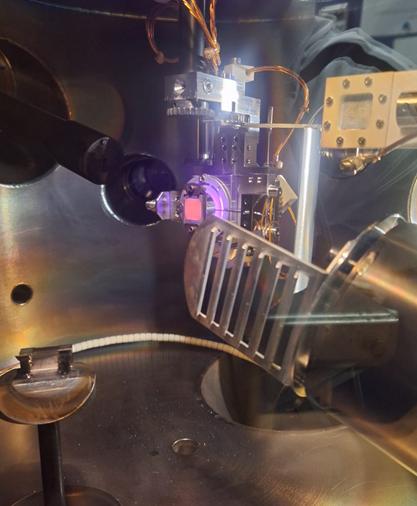

The sputtering chamber, directly connected to one of the two PLD chambers, enables successive depositions without intermediate venting. The sputtering system, assembled by the platform team, was custom-built to fit perfectly with the PLD configuration. It is equipped with a 2” DC magnetron, enabling, among other things, the deposition of metallic materials (platinum, copper, etc…) which, combined with the functional oxides developed by the “thin-film oxides” team, allows studies in the field of spintronics.

The platform has also improved the heating of the pulsed laser deposited samples. In addition to the existing resistive heating system, a new laser heating system has been installed. This new heating system heats the back of the sample holder using a laser (class 4) with a wavelength of 980 nm. The temperature is measured at the rear with a pyrometer. With this new device higher temperatures can be reached (at least 1100°C compared to 900°C for the resistive heating). Temperature changes can be more rapid, and annealing in an oxygen atmosphere is feasible, since laser heating eliminates issues like thermal inertia and contact oxidation.

For more information on these two new pieces of equipment, jointly funded by PEPR SPIN, CNRS, IPCMS and the “Thin-Film Oxides” team, please contact one of the PLD platform members.