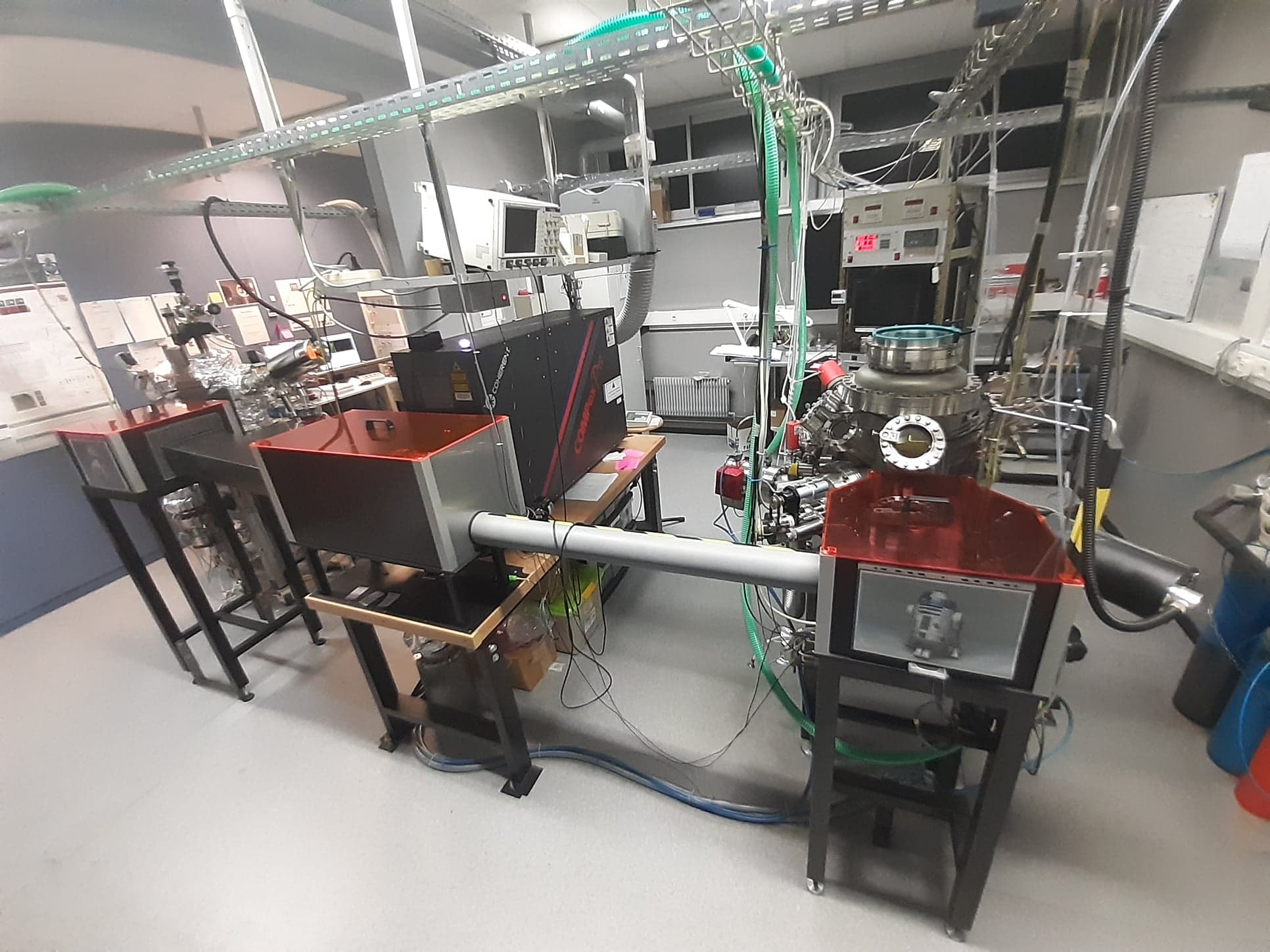

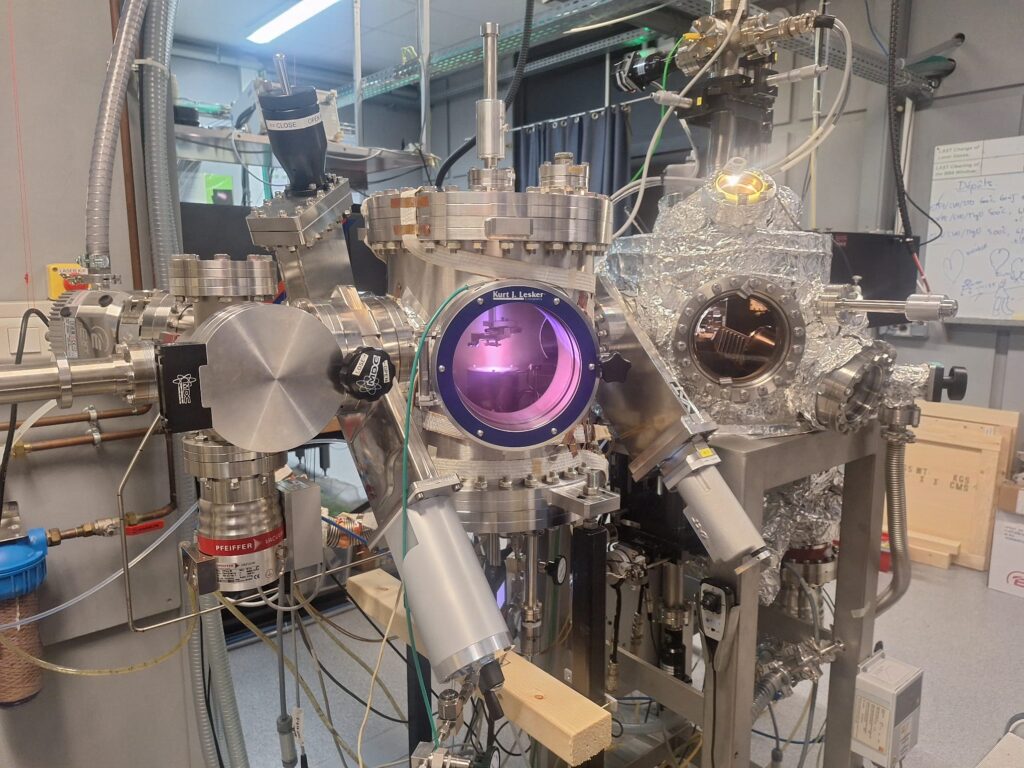

The pulsed laser deposition platform, certified ISO 9001 : 2015, is equipped with two chambers and one KrF laser

Contacts

Scientific in charge

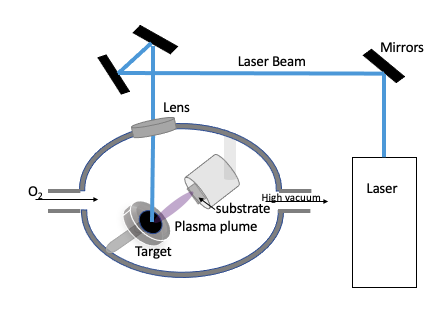

Ablation principle

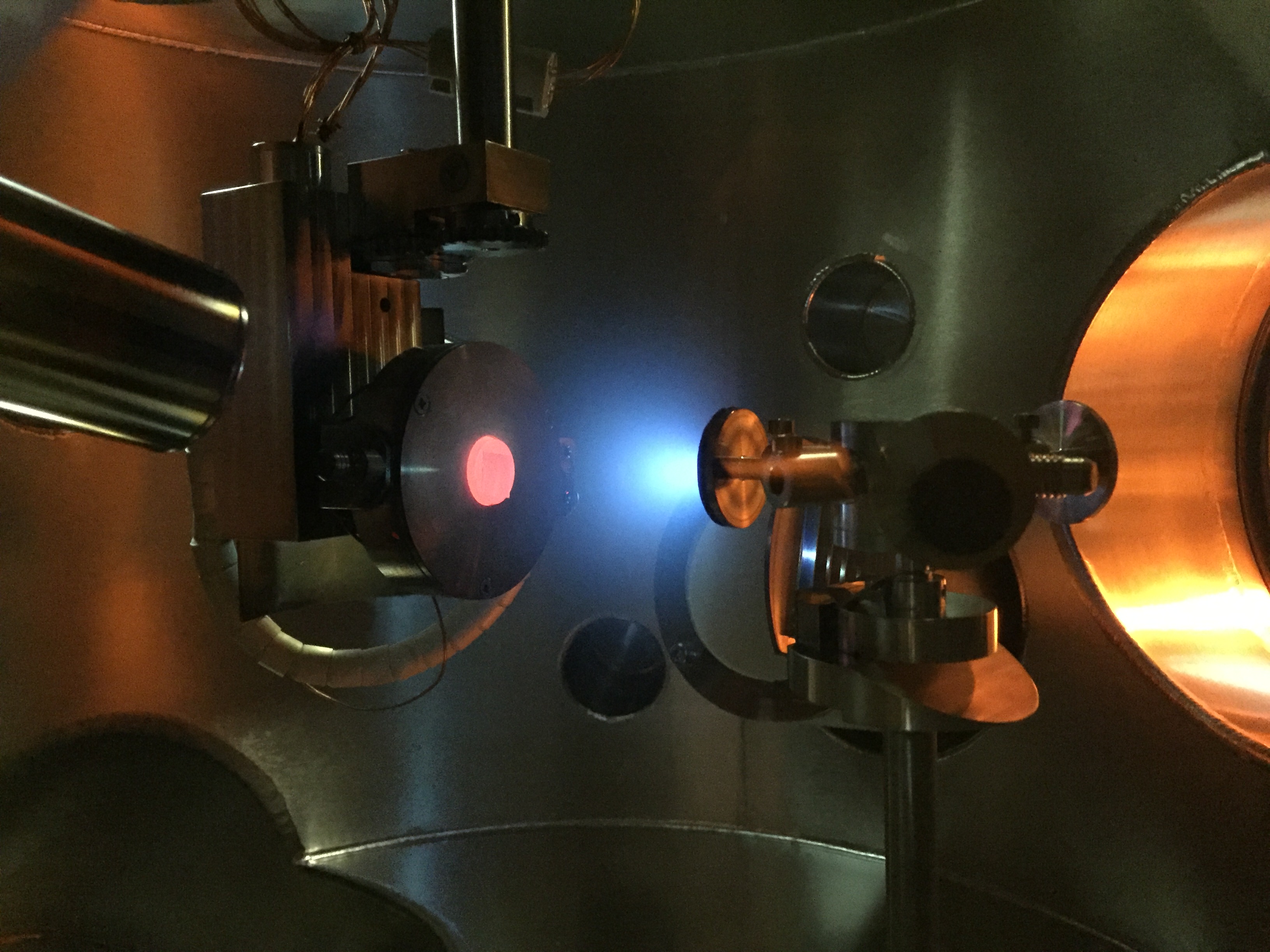

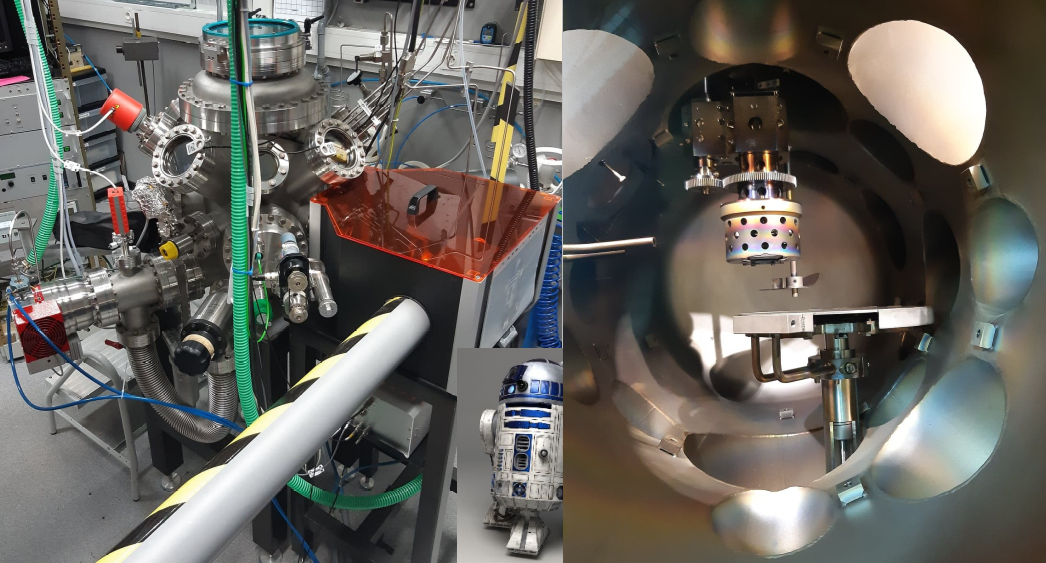

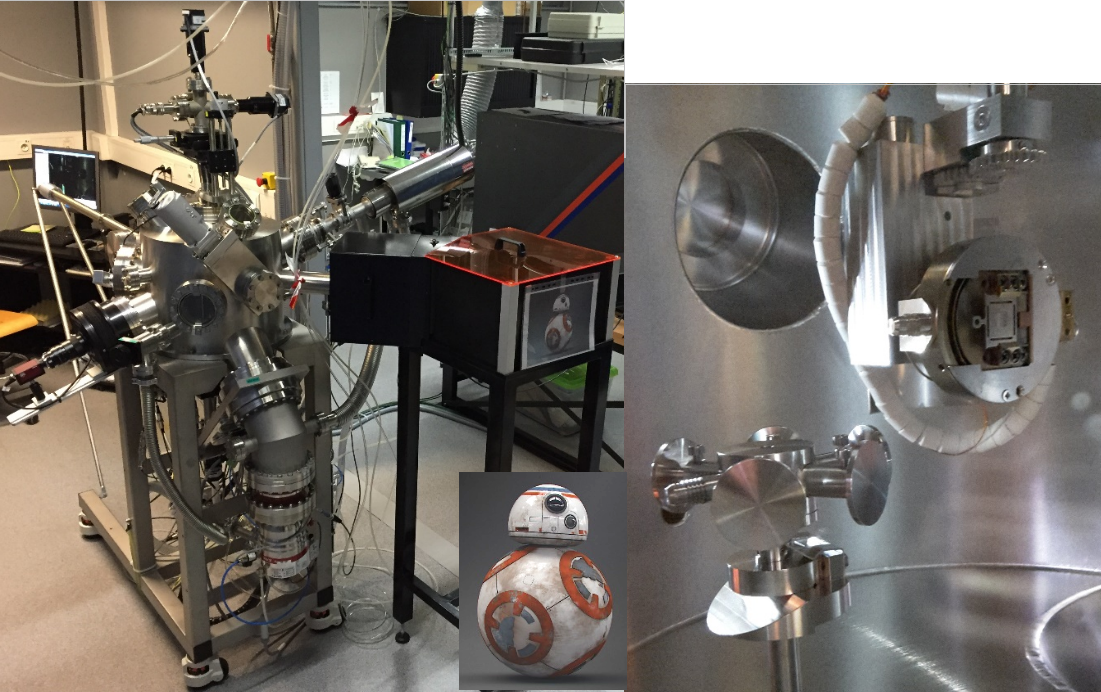

Pulsed Laser Deposition (PLD) is a physical method of thin film deposition. PLD involves focusing a high-energy UV laser on a target consisting of the material to be deposited. The energy transmitted to the target is sufficient to ablate and ionise the surface atoms. A plasma “plume” is formed perpendicular to the target. Opposite the target is the substrate on which the ejected material condenses. The target and substrate are placed in a controlled atmosphere chamber. The IPCMS has two laser ablation chambers: one homemade (nicknamed “R2D2”) and one manufactured by TSST (“BB8”).

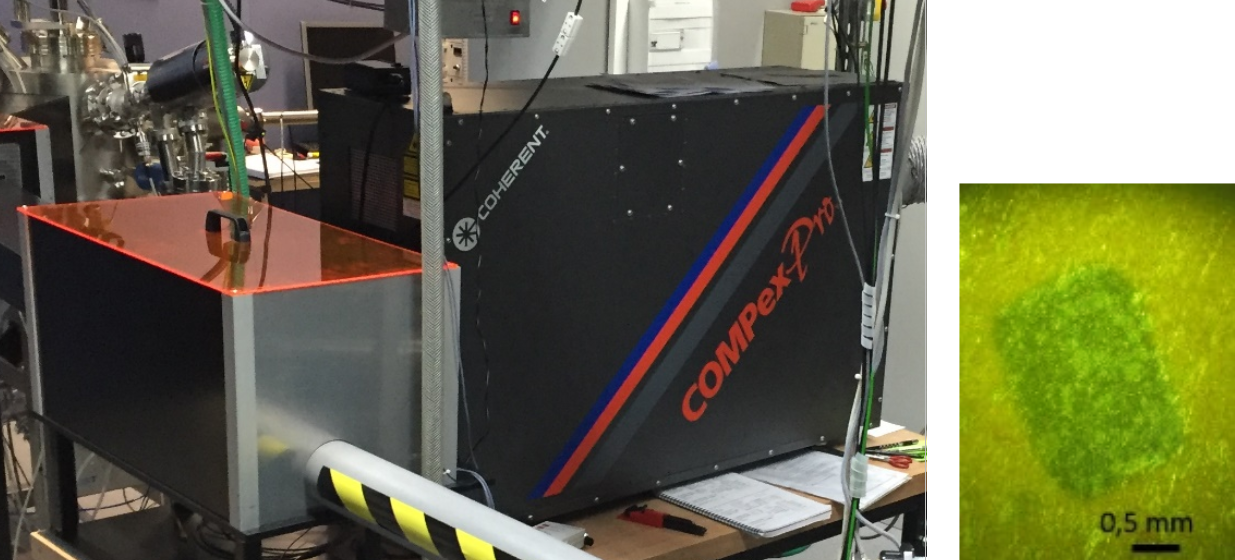

Excimer Laser (Compex Pro COHERENT)

Krypton / Fluorine laser of wavelength λ=248nm. Maximum energy of 400 mJ, with a fluence of up to 5 J/cm². Very well defined laser impact with a rectangular shape and an area of 0.016 ± 0.003 cm². An optical box at the laser exit allows the laser beam to be directed to either of the two ablation chambers that equip the laboratory: R2D2 or BB8

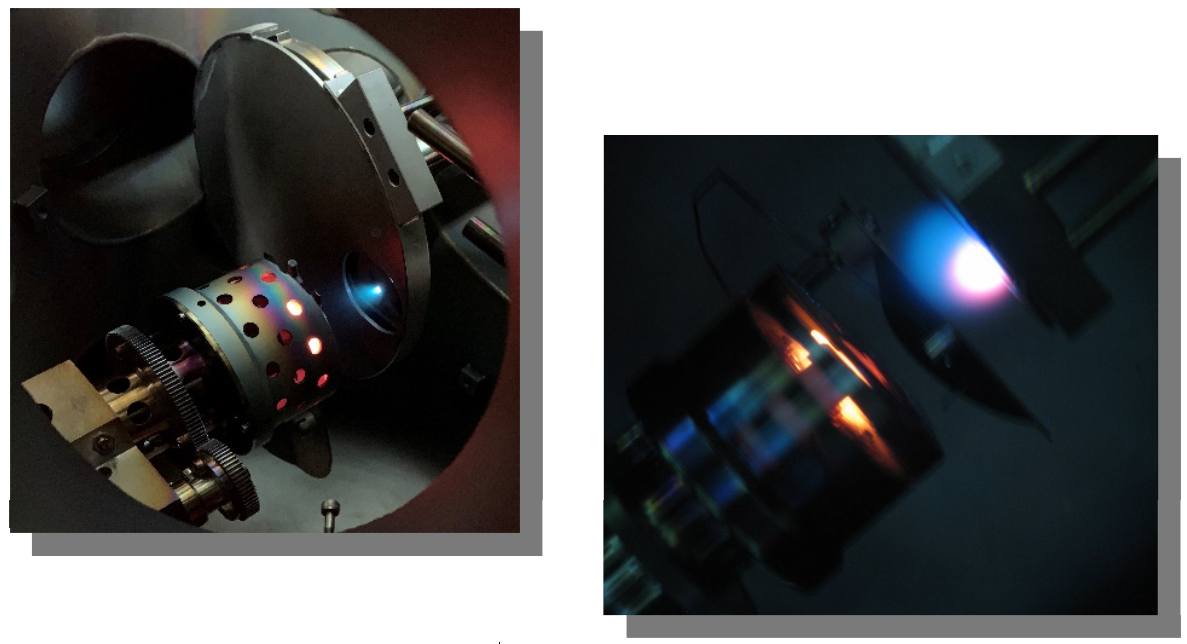

“R2D2” depository chamber :

Carousel for up to 6 targets simultaneously in the ablation chamber. Base vacuum of 1 x 10-8 mbar. Atmosphere during deposition: partial pressure of oxygen or dry air. Radiation heating of the substrate up to 800°C with the possibility of rotation. Laser displacements by optical mirrors allowing co-ablation deposition.

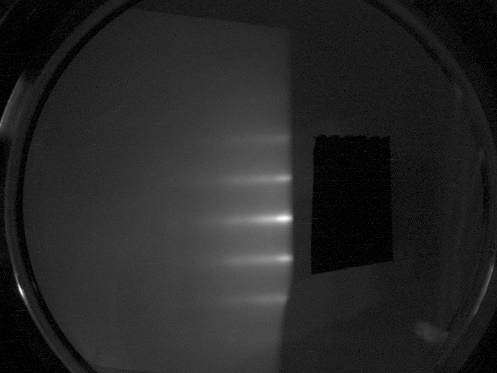

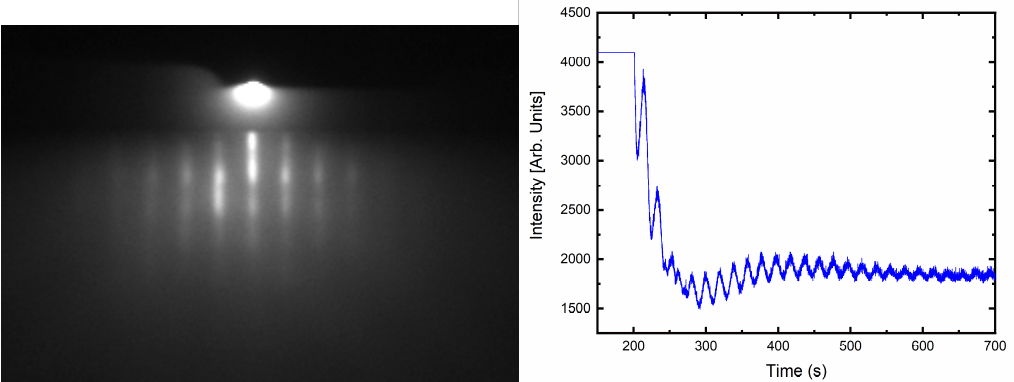

RHEED diffraction pattern of a La2/3Sr1/3MnO3 film deposited on a SrTiO3 (STO) substrate

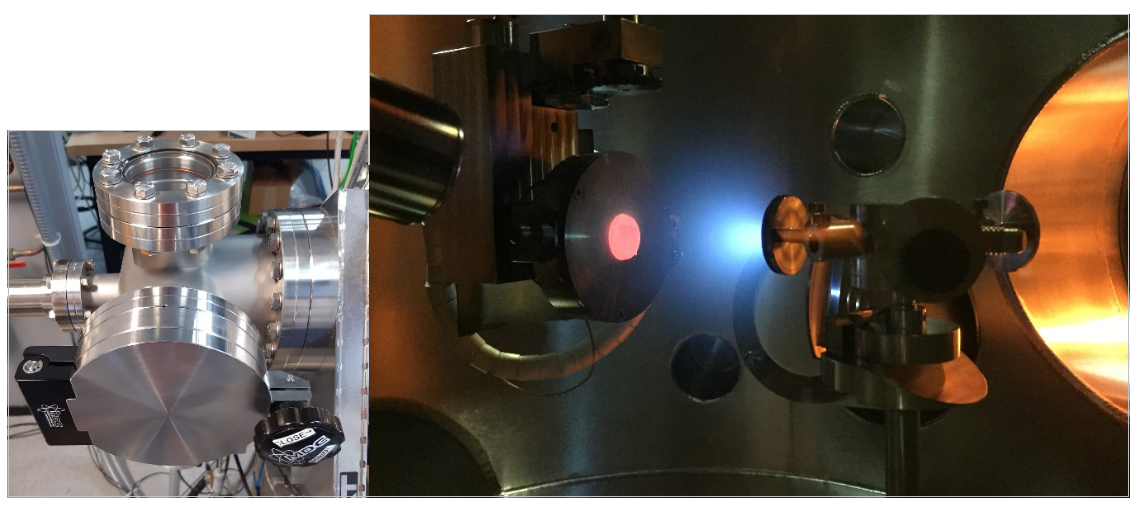

“BB8” depository chamber :

Motorised carousel allowing up to 5 targets simultaneously in the ablation chamber Base vacuum of 8 x 10-9 mbar. Atmosphere during deposition: Ar or O2 partial pressure. Resistive heating of the substrate up to 900°C or Laser heating up to 1100°C. Substrate and target introduction with a loadlock. High pressure RHEED for diffraction imaging and RHEED oscillation tracking up to 0.3 mbar partial pressure.

Diffraction pattern and RHEED oscillations of an NdNiO3 thin film deposited on a SrTiO3 (STO) substrate.

Examples of thin layers :

The PLD chambers are used to elaborate functional oxides thin films such as

- Magnetoelectric compounds: Ga2-xFexO3

- Double perovskite Bi2FeCrO6 for photovoltaic applications

- Rare earth nickelate: NdNiO3

- Spinel: FeV2O4, VFe2O4, GeFe2O4, CoFe2O4

- Lanthanum strontium manganite: La1-xSrxMnO

More informations about the reasearch projects are available here

Video

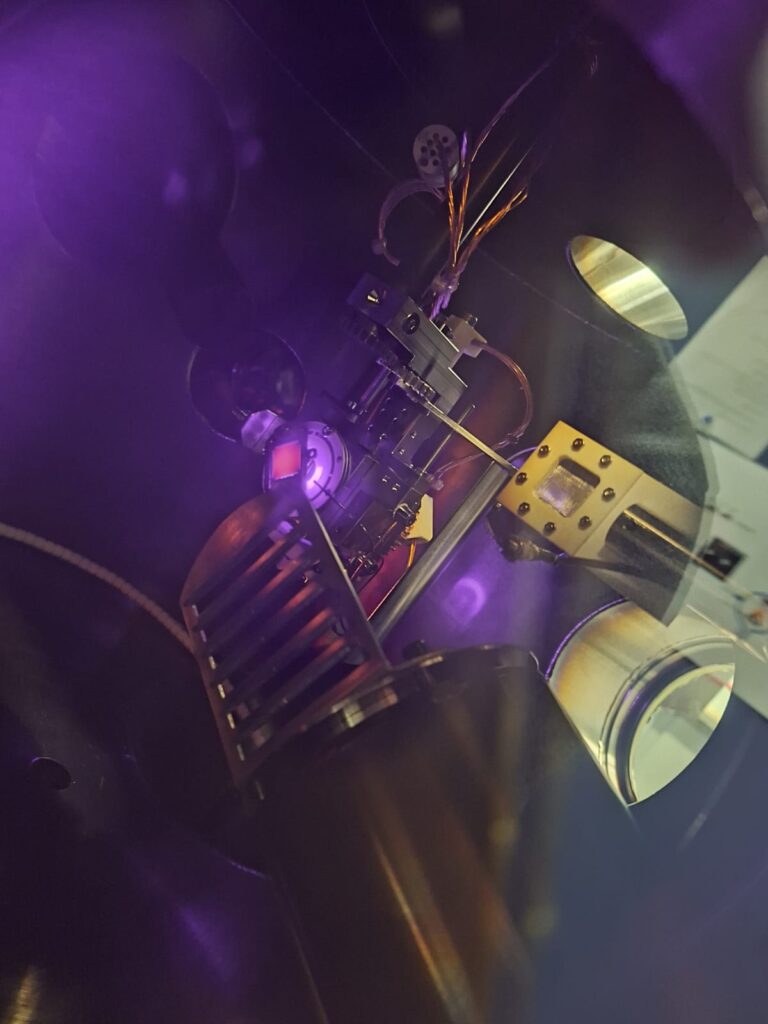

example of a deposition on R2D2 using two targets

Sputtering chamber :

The sputtering chamber, directly connected to the BB8 PLD chamber, enables successive depositions without intermediate venting. The sputtering system, assembled by the platform team, was custom-built to fit perfectly with the PLD configuration. It is equipped with a 2” DC magnetron, enabling, among other things, the deposition of metallic materials (platinum, copper, etc…) which, combined with the functional oxides developed by the “thin-film oxides” team, allows studies in the field of spintronics.

Photo gallery